Learning, office, entertainment, leisure, etc. in life are inseparable from a top-notch computer in quality and performance, which provides us with various conveniences. With the rapid development of computers nowadays, we always have to face a one-in-a-million situation, that is, to select products that satisfy ourselves from all kinds of computers. Under normal circumstances, we will consider the quality, function and characteristics of the computer itself, but in fact, the power supply of the computer is also something we need to pay attention to.

Friends who have used computers know that if the computer is used for a long time, not only the CPU temperature of the fuselage will rise, causing a freeze, but the charging power supply will also become hot, affecting the charging rate, and even burn out in severe cases. Therefore, many people will have difficulties in the choice of power supply housing. I don't know whether to choose plastic or aluminum alloy. Next, Chicco will analyze it for you.

The power supply shell made of plastic is more common in life. This is because the weight of plastic is light, it is very convenient to carry out, and the cost is relatively cheap. This is why many power supply shells use more plastic, after all, they are put on the market. Zhongneng can reduce its selling price in a certain aspect, which can form a certain advantage. But it also has inevitable drawbacks. On the one hand, it is easy to cause damage when subjected to external impact, and on the other hand, it is not easy to dissipate heat. The heat generated by the battery core and circuit board is difficult to dissipate into the air through the plastic. Easily cause damage to electronic parts.

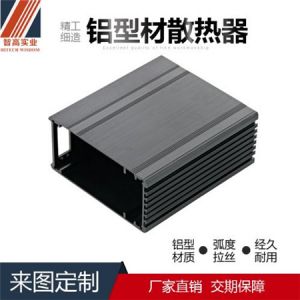

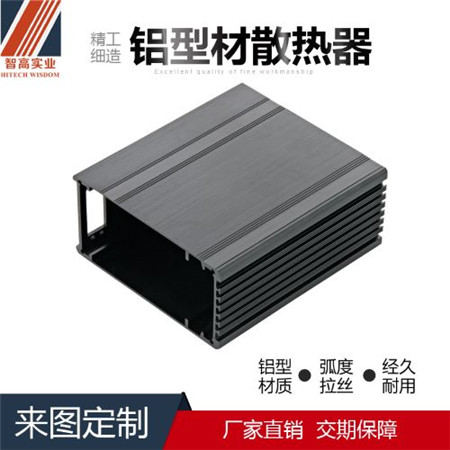

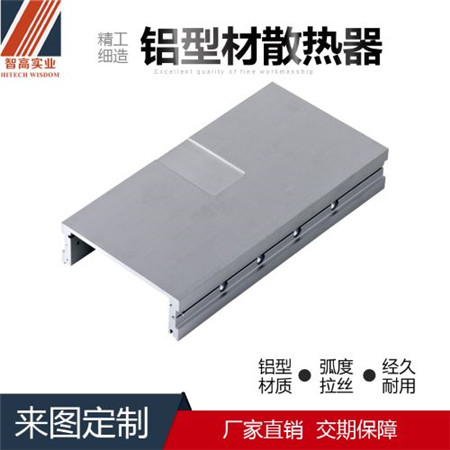

It is believed that many people will think that it will be too heavy and heavy to make aluminum alloy as the material of the power supply shell, but it is not the case. Today's aluminum alloy can also be lighter by the ratio of materials, which is convenient for us to carry, as we see now The aluminum case of the power bank is a good example. Moreover, the aluminum alloy power supply shell can be made more sturdy, and it can do better in anti-fall and anti-knocking. Of course, the most important thing is to mention the heat dissipation function. Aluminum alloy has high thermal conductivity and is not easily deformed in high temperature. It can efficiently and quickly conduct the heat generated by internal electronic parts into the air, which can provide a safe and stable environment for the power supply. . Compared with plastic products, the slight disadvantage is that the price is relatively high.

The power supply casing must also be precision cast, which is not enough to consider the price. Durability and performance are factors that cannot be ignored. Zhigao Industry specializes in processing all kinds of aluminum alloy shells. It is also ingenious in the production and processing of power shells. According to customers' drawings and samples, processing and customization are carried out to ensure that each power shell is accurate in size and excellent in quality to meet the needs of various industries. Installation requirements.