Generally speaking, the stability and quality of LED lamps are critical to the heat dissipation of the lamp body. The heat dissipation of high-brightness LED lamps on the market often uses natural heat dissipation, and the effect is not very ideal.

LED lamps are composed of LEDs, heat dissipation structures, and driver lenses. Therefore, heat dissipation is also an important part. If the LED does not dissipate heat well, its lifespan will also be affected.

The heat dissipation problem is the main obstacle in the development of LEDs as lighting objects, so reducing the temperature of LEDs through various means has become a problem discussed by major manufacturers. As people pay more and more attention to the heat dissipation of LEDs, various heat dissipation technologies have also been applied to LED lighting technology!

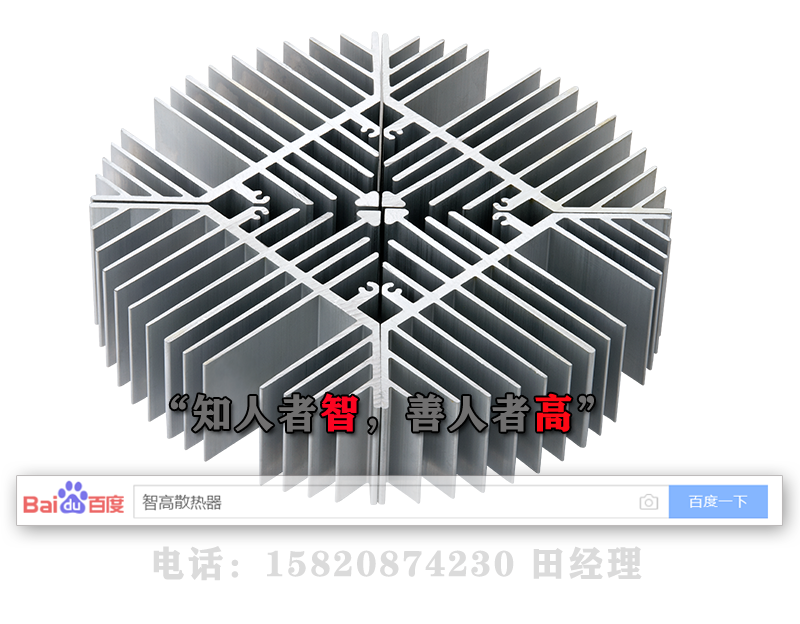

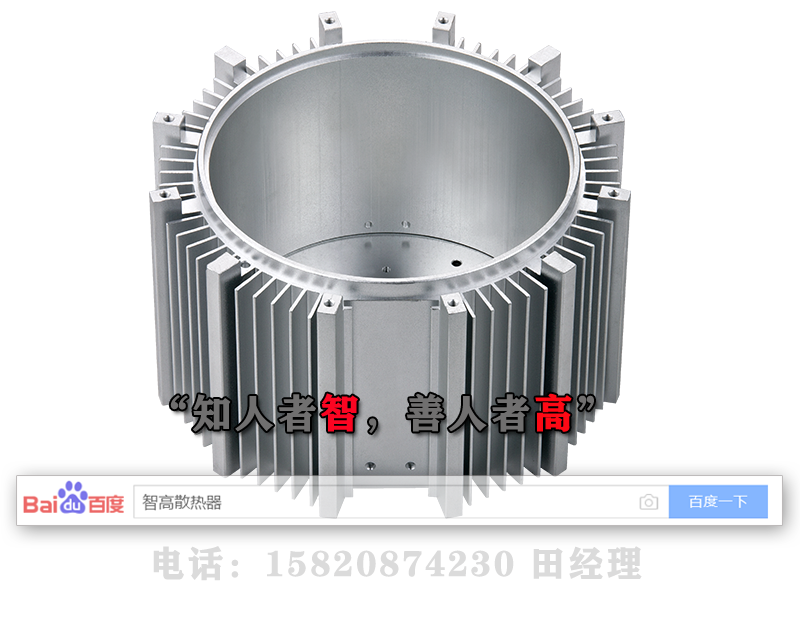

Zhigao Industrial took a fancy to the problem of how LEDs should dissipate heat and developed an LED aluminum alloy heat sink, which can effectively help the LED to dissipate heat and extend the life of the LED.

The main function of the LED aluminum radiator produced by Chicco is to continuously export and dissipate the heat generated during the operation of the LED chip to the environment, keeping the temperature of the chip within the required range, so as to ensure that the LED lamp can work normally .

First of all, for a radiator of a certain shape, the thermal conductivity is mainly related to the thermal conductivity of the radiator material. The larger the thermal conductivity, the smaller the thermal conductivity and the better the thermal conductivity. The LED heat sink produced by Zhi Gao Industrial uses aluminum alloy as the main manufacturing material. Aluminum alloy has a better thermal conductivity effect. With the heat conduction resistance of the heat sink, it can effectively dissipate the LED lights. Aluminum alloy radiator can be used as a new type of insulation and heat dissipation material for various power lamps.

Secondly, under certain environmental conditions, the thermal resistance of heat dissipation mainly depends on the heat dissipation area of the radiator and the emissivity coefficient of the surface material of the radiator. The larger the heat dissipation area and the higher the emissivity, the smaller the heat dissipation resistance and the better the heat dissipation effect.

The LED lamp radiator produced by Zhigao Industry has a certain heat dissipation area. At the same time, the material of the radiator made by Zhigao Industry is aluminum alloy, which has a certain thermal conductivity and high thermal radiation coefficient.

In addition, the aluminum alloy thermal material selected by Zhigao Industry itself has the characteristics of light weight, easy processing, and low price.

LED lighting applications and heat dissipation technology requirements are different, so that the LED lighting heat dissipation component industry presents different competitive characteristics. Zhigao Industry has always adhered to the talent concept of "knowing others, and good ones", boldly cultivate and use all kinds of talents, and is committed to producing better LED radiators.