Once summer comes, we not only have to consider how to cool down to make ourselves comfortable, but also worry about the high temperature of the home appliances we use. As soon as winter comes, if you install heating in your home, you will be concerned about the effect of heating equipment. Surrounding home appliances, we inevitably have to face the problem of heat dissipation. Therefore, our electronic products are indispensable for the company of radiators. Although most of them are difficult to detect, they do play a vital role.

Electronic radiators are usually heat sinks for heat dissipation of high-power electronic components, without the need for external power supplies to dissipate heat and cool by themselves. Timely and effective heat dissipation of electronic products is the most direct and effective way to increase their service life. Therefore, the service life and heat dissipation effect of electronic radiators are extremely critical. This requires the material, processing technology and component quality of its heat sink. Make a request, and Chicco is very pragmatic at this point.

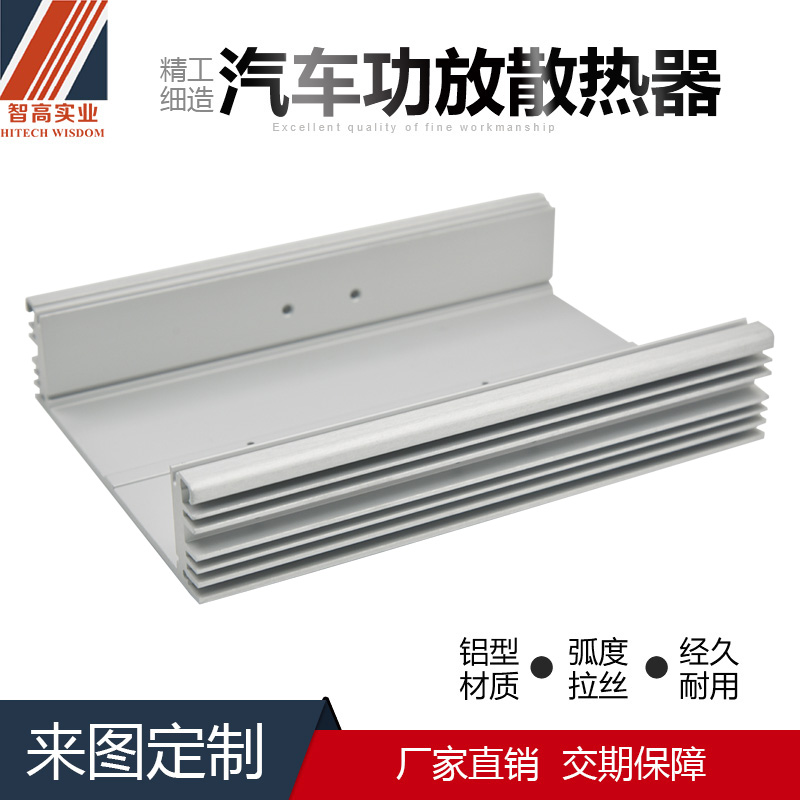

The electronic radiator launched by Chicco eliminates the desire for cheapness and shoddy manufacture. The material is made of aluminum 6063/6061, which has beautiful appearance, stable heat absorption, fast heat dissipation, corrosion resistance and low cost. In order to increase the heat dissipation efficiency, the plug-in type is mostly adopted in the shape design, which greatly increases the heat dissipation area and the contact area between the radiator and the air, so that it can absorb and dissipate heat to a greater extent. Moreover, when the radiator works normally, no noise will be generated, and stable and quiet heat dissipation can be achieved.

In order to enhance the durability of the radiator, post-processing is also essential. In addition to the selection of corrosion-resistant materials, a number of processing will be performed on the surface of the radiator. First of all, it is necessary to clean the surface of the profile by chemical or physical methods to expose the pure matrix in order to obtain a complete and dense artificial oxide film. After surface pretreatment, under certain process conditions, the surface of the substrate undergoes anodization to form a dense, porous, and strong adsorption AL203 film. A solid barrier is formed, which can effectively eliminate the oxidation and corrosion reaction and play an anti-corrosion effect. Therefore, the radiator exposed to the complex environment can have a longer life and use more durable.

Chicco electronic radiator has stable heat dissipation, high quality and durability, helping your home appliances to operate safely and worry-free.