Surface crack defect characteristics of aluminum profile radiator: The surface of the aluminum profile presents a longitudinal fish-like repetitive interval break pattern, which is severely directly disconnected. So what causes tearing cracks on the surface of the aluminum radiator? How should it be solved?

The main causes of surface cracks on aluminum radiators are as follows:

1. The extrusion coefficient of aluminum profile is too large, the extrusion temperature is too high (three temperatures of rod, barrel, and die), and the extrusion speed is too fast;

2. The squeezing force is unstable, high and low, or the speed difference between multiple speed adjustments is obvious, and the speed changes suddenly when shifting;

3. When the aluminum alloy profile is extruded, the head end is pressed (punching) too fast, the tail end is running fast or not slowed down, and a large amount of aluminum infiltrates in the dead zone;

Fourth, the quality of aluminum rods is poor, the rods are overburnt, large grains, and loose. Overpressure (V3 aluminum) is too thin;

5. The flow rate ratio of the extrusion die is seriously out of adjustment. The design and manufacture are unreasonable.

Methods to eliminate surface cracks on aluminum radiators:

1. Profiles with excessive extrusion coefficient can be produced on a small machine, and aluminum profiles should be produced with a suitable extrusion ratio; in addition, the three extrusion temperatures should be strictly controlled according to the production process requirements, and the appropriate extrusion speed should be used;

2. The operator is concentrated, the speed is stable, the pressure cannot be higher or lower, and the manual operation is coordinated when shifting gears;

3. The front and back ends of the aluminum profile stop printing are dead zones or V3 volume (aluminum rod surface) aluminum, which has many impurities, poor quality and insufficient viscosity, so the extrusion speed of the profile head and tail ends should be slowed down;

Fourth, the surface of the aluminum rod should be fine, clean and free of oil stains, and the internal organization should meet the standard, and the remaining pressure should be kept normally (5% of the rod length);

5. Extrusion die designers should design and manufacture qualified die with uniform flow rate.

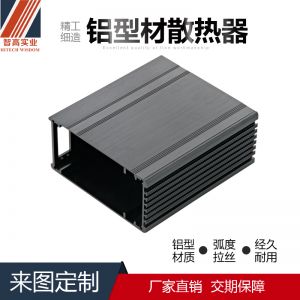

Dongguan Zhigao Industrial Co., Ltd. specializes in processing aluminum automotive power amplifier radiators, aluminum home audio panels and aluminum LED radiators. Welcome to order.

b12fa69420bccfc50bea0f23b71e6d26_%E9%93%9D%E5%9E%8B%E6%9D%90%E6%95%A3%E7%83%AD%E5%99%A81(2).jpg