Blistering or skinning on the surface of extruded aluminum radiator: Convex bubbles appear on the surface of the product, usually at the head and tail, complete called bubbles, and broken ones are called skins.

一. Reasons for bubbles and peeling of extruded aluminum radiator products:

1. The extruded cylinder and the extruded pad are worn out, the size of the extruded cylinder and the extruded pad are not properly matched, and the diameter difference of the used gasket exceeds the allowable value;

2. The squeeze cylinder and the squeeze pad are too dirty, with oil, moisture, graphite, etc.;

3. Lubricating oil contains water;

4. There are too many shovel grooves on the surface of the ingot, too deep, or there are pores, sand holes, loose tissue, and oil on the surface of the ingot;

5. When changing the alloy, the inside of the barrel was not cleaned;

6. Extrusion barrel temperature and extrusion ingot temperature are too high;

7. The ingot temperature and size exceed the allowable negative deviation;

8. The ingot is too long, the filling is too fast, and the temperature of the ingot is uneven, causing non-drum filling, so the exhaust in the cylinder is not complete, or the operation is improper, and the exhaust process is not performed;

9. The die hole design is unreasonable, or the residual material is improperly cut, the residual material in the diversion hole and the diversion hole is partially taken out, and the gas in the gap enters the surface during extrusion.

2. Elimination method:

1. Reasonably design the matching size of the extrusion cylinder and the extrusion gasket, and check the tool size frequently to ensure that it meets the requirements. If the extrusion cylinder has a big belly, it should be repaired in time, and the extrusion gasket should not be out of tolerance;

2. Keep the surface of tools and ingots clean, smooth and dry;

3. When replacing the alloy, thoroughly clean the barrel;

4. Check equipment and instruments frequently to prevent excessive temperature and speed;

5. Strictly implement process regulations and various systems;

6. Reasonably design and manufacture tools and molds, and design the diversion holes and diversion holes to have an internal slope of 1 to 3 degrees;

7. Strictly operate, cut the residual material correctly and completely exhaust.

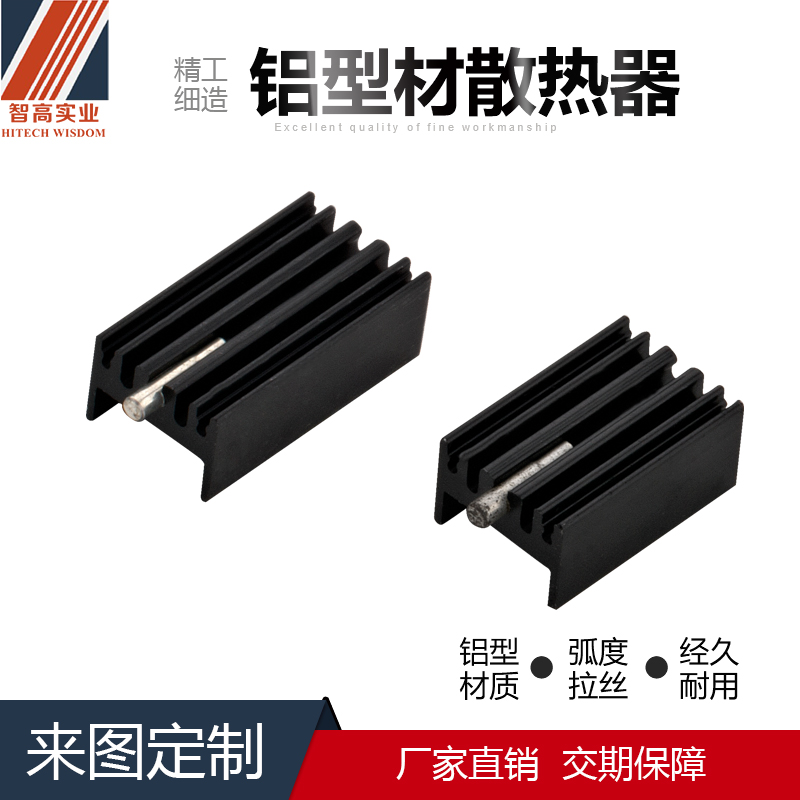

Dongguan Zhigao Industrial Co., Ltd. specializes in processing aluminum automotive power amplifier radiators, aluminum home audio panels and aluminum LED radiators. Welcome to order.