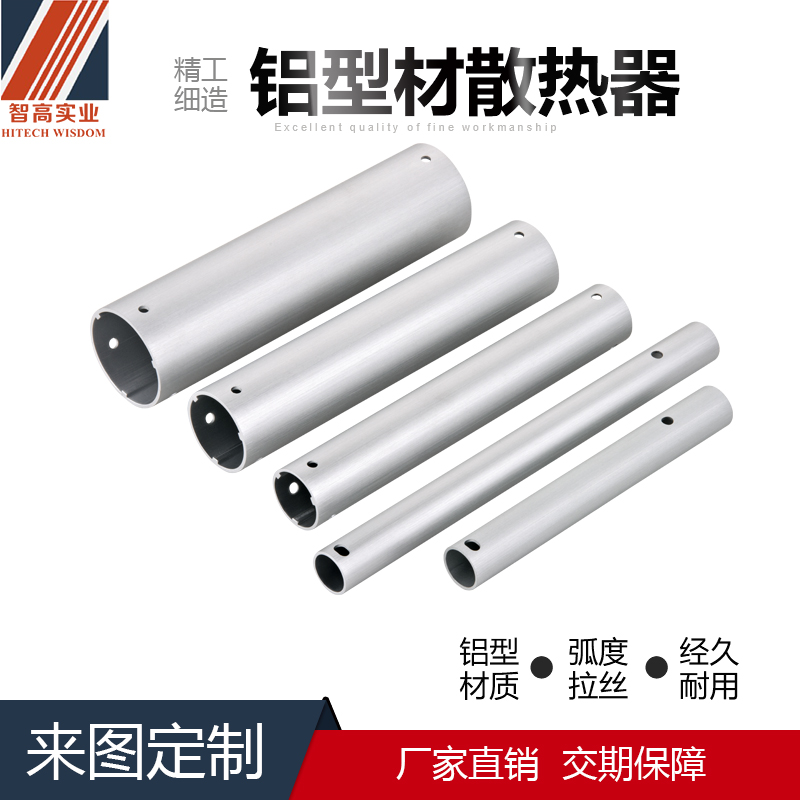

Aluminum heat sinks are widely used because of their good plasticity, moderate heat treatment strength, good welding performance, and gorgeous color on the surface after anodizing. However, some problems often occur in the production process, resulting in low quality of aluminum heat sinks, reduced yields, increased production costs, and reduced benefits, resulting in a decline in the company's market competitiveness. Therefore, solving the defects of aluminum heat sinks is an important aspect for companies to improve their competitiveness. Dongguan Chicco shared the causes of scratches, scratches and bruises on aluminum heat sinks and their solutions.

Scratches, abrasions, and bruises are the surface damage of the aluminum profile of the heat sink when the profile flows out from the die hole and comes into contact with tools, equipment, etc. in the subsequent process.

cause

1. There are bare metal on the discharge rail or swing bed or hard inclusions in the graphite strip, which will scratch the surface of the aluminum heat sink when it comes in contact with the profile.

2. When the fork rod sends the profile from the discharge track to the swing bed, the profile is bruised due to the excessive speed.

3. There are impurities or segregation of ingot components on the surface of the ingot. When there are a lot of segregation floats on the surface of the ingot and the ingot has not been homogenized or the homogenization treatment effect is not good, there are a certain number of hard metal particles in the ingot, and when the metal flows through the working belt during the extrusion process , These segregation floats or hard metal particles adhere to the surface of the working belt or cause damage to the working belt, and eventually cause scratches on the surface of the profile.

4. There are debris on the mold cavity or working belt, and the hardness of the working belt of the mold is low, which makes the surface of the working belt injured during extrusion and scratches the aluminum heat sink.

5. During transportation, friction or extrusion between the profiles causes damage to the aluminum profile heat sink.

Three, the solution

1. Strengthen the control of the quality of ingots.

2. To improve the quality of mold repair, mold nitriding regularly and strictly implement nitriding process.

3. Use soft felt to isolate the profile from the auxiliary device to minimize the contact damage between the profile and the auxiliary device.

4. Handle with care during production, try to avoid dragging or flipping the aluminum heat sink at will.

Dongguan Zhigao Industrial Co., Ltd. specializes in processing aluminum automotive power amplifier radiators, aluminum home audio panels and aluminum LED radiators. Welcome to order.