The heat dissipation of the LED display lamp housing has different considerations depending on the power size and the place of use.

1. Air fluid mechanics uses the shape of the lamp housing to create convective air, which is a cost-effective way to enhance heat dissipation.

2. Thermally conductive plastic shell, filled with thermally conductive material during injection molding of the plastic shell to increase the thermal conductivity and heat dissipation capacity of the plastic shell.

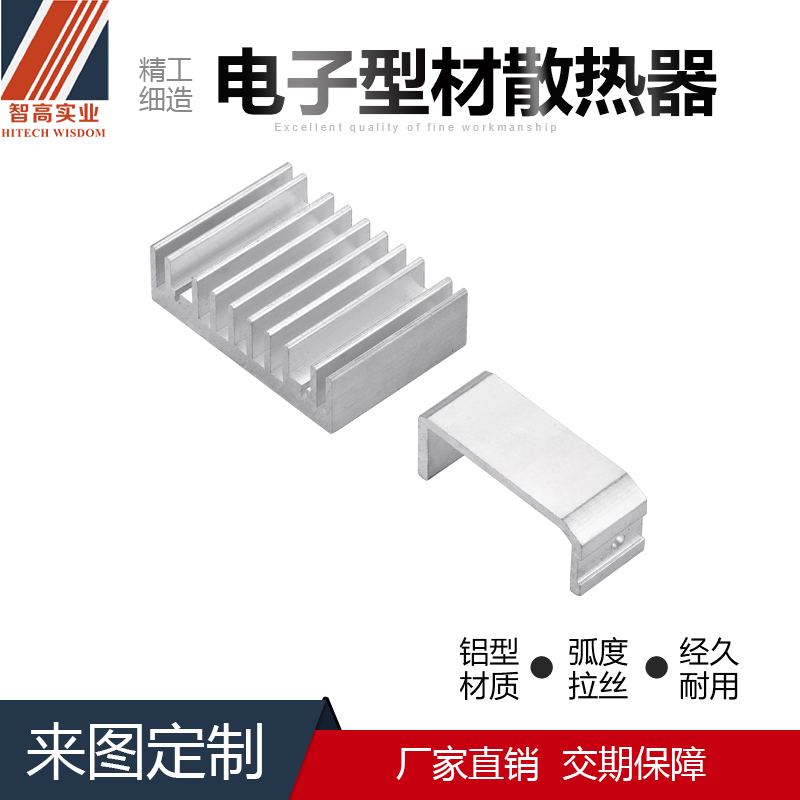

3. Aluminum heat sink, this is the most common way of heat dissipation. Use aluminum heat sink as part of the shell to increase the heat dissipation area.

4. Surface radiation heat dissipation treatment, the surface of the lamp housing is treated with radiation heat dissipation. The simple method is to apply radiation heat dissipation paint to take the heat away from the surface of the lamp housing by radiation.

5. Heat pipe heat dissipation, using heat pipe technology to conduct heat from the LED full-color display chip to the heat dissipation fins of the shell. It is a common design in large lamps, such as street lamps.

6. Fan heat dissipation, long-life and high-efficiency fan is used inside the lamp housing to enhance heat dissipation. This method has low cost and good effect. However, it is troublesome to change the fan and it is not suitable for outdoor use. This design is relatively rare.

7. Liquid bulb, using liquid bulb packaging technology to fill the lamp body bulb with a transparent liquid with high thermal conductivity. This is the current technology that uses the light-emitting surface of the LED chip to conduct heat and heat dissipation in addition to the principle of light reflection. ,

Dongguan Zhigao Industrial Co., Ltd. specializes in processing aluminum power amplifier radiators, home audio panels, and LED radiators. Welcome to order.