At present, the biggest technical problem of LED lighting fixtures is heat dissipation. Poor heat dissipation has led to LED driving power supplies and electrolytic capacitors that have become shortcomings in the further development of LED lighting fixtures, and the cause of the premature decay of LED light sources.

In the luminaire solution using LED light source, because the LED light source works at low voltage (VF=3.2V) and high current (IF=300-700mA), the heat is very strong. The space of traditional luminaires is narrow and small area of heat dissipation It is difficult for the heat sink to dissipate heat quickly. Although a variety of heat dissipation schemes were adopted, the results were not satisfactory and became an unsolvable problem for LED lighting fixtures. We are always looking for materials that are easy to use, have good thermal conductivity, and are low-cost.

At present, after the LED light source is powered on, about 30% of the electric energy is converted into light energy, and the rest is converted into heat energy. Therefore, it is a key technology for the structural design of LED lamps to export so much heat energy as soon as possible. The heat energy needs to pass through heat conduction, heat convection, and heat. Only radiation can be emitted. Only by dissipating heat as soon as possible can the cavity temperature in the LED lamp be effectively reduced, and the power supply can be protected from working in a long-lasting high temperature environment, and the premature aging of the LED light source due to long-term high temperature operation can be avoided.

The heat dissipation path of LED lighting:

Because the LED light source itself does not have infrared or ultraviolet rays, the LED light source itself does not have the radiation heat dissipation function. The heat dissipation method of the LED lighting fixture can only extract heat through the radiator closely combined with the LED lamp bead plate. The radiator must have the functions of heat conduction, heat convection, and heat radiation.

Any radiator, in addition to quickly transferring heat from the heat source to the surface of the radiator, the most important thing is to dissipate heat into the air by convection and radiation. Heat conduction only solves the heat transfer, and thermal convection is the main function of the radiator. The heat dissipation performance is mainly determined by the heat dissipation area, shape, and the ability of natural convection intensity. Thermal radiation is only an auxiliary function. Generally speaking, if the distance from the heat source to the surface of the radiator is less than 5mm, as long as the thermal conductivity of the material is greater than 5, the heat can be exported, and the rest of the heat dissipation must be dominated by thermal convection.

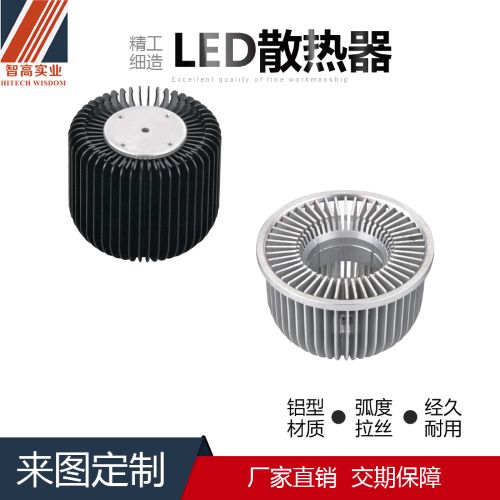

aluminum alloy radiator

Most of the LED lighting sources still use low voltage (VF=3.2V) and high current (IF=200-700mA) LED lamp beads. Due to the high heat during operation, aluminum alloy with higher thermal conductivity must be used. Usually there are die-cast aluminum radiators, extruded aluminum radiators, and stamped aluminum radiators. Die-casting aluminum radiator is a technology of pressure casting parts. The liquid zinc, copper, and aluminum alloy is poured into the inlet of the die-casting machine, and the die-casting machine is die-casted to cast a radiator with a pre-designed mold.

The extruded aluminum radiator is to extrude liquid aluminum through a fixed die, and then cut the bar into the required shape of the radiator through machining, and the later processing cost is relatively high. Extruded aluminum radiator radiating fins can be made very thin, and the heat dissipation area is maximized. When the radiating fins work, air convection is automatically formed to diffuse heat, and the heat dissipation effect is better. Commonly used materials are AL6061 and AL6

Zhigao Industry, as a professional manufacturer of high-end exquisite LED radiators, provides LED manufacturers with high-quality LED radiators, dedicated to dissipate high heat, and spare no effort to create high-quality products, so that the development of LED lamps will no longer be hindered by heat.