Ingenuity and unique skills, and meticulous craftsmanship to create high-quality products, this is a criterion and belief in the pursuit of exquisiteness in the manufacturing industry. Zhigao Industry is no exception in the manufacturing of automotive power amplifier radiators. fine. Now let's introduce to you a key step in the manufacture of car power amplifier radiators-wire drawing process.

Friends who have been in contact with radiators are no strangers to the term "drawing", but they may not have a thorough understanding of "drawing". In fact, the wire drawing process is a kind of metal processing process. It is a method to improve the surface quality of the work piece by rubbing back and forth on the metal surface by external force to improve the surface finish of the work piece and make the surface texture present a certain regular distribution.

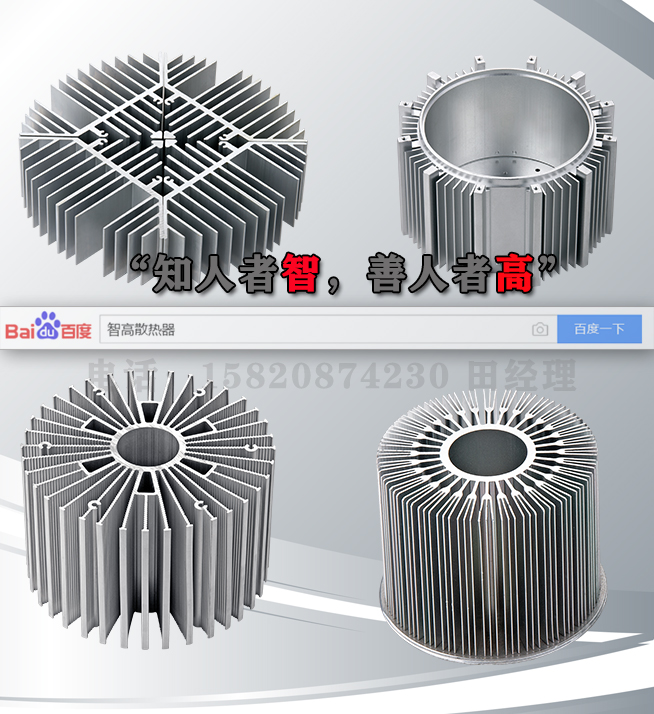

Chicco's car power amplifier radiator can not only improve the appearance of the radiator, but also increase the heat-receiving area and increase the heat-absorbing capacity by means of the wire drawing process. According to the different textures, the drawing process is also unique. The common ones are straight-grain drawing, chaotic-grain drawing, thread drawing and corrugated drawing.

Ingenuity and unique skills, and meticulous craftsmanship to create high-quality products, this is a criterion and belief in the pursuit of exquisiteness in the manufacturing industry. Zhigao Industry is no exception in the manufacturing of automotive power amplifier radiators. fine. Now let's introduce to you a key step in the manufacture of car power amplifier radiators-wire drawing process.

Friends who have been in contact with radiators are no strangers to the term "drawing", but they may not have a thorough understanding of "drawing". In fact, the wire drawing process is a kind of metal processing process. It is a method to improve the surface quality of the work piece by rubbing back and forth on the metal surface by external force to improve the surface finish of the work piece and make the surface texture present a certain regular distribution.

Chicco's car power amplifier radiator can not only improve the appearance of the radiator, but also increase the heat-receiving area and increase the heat-absorbing capacity by means of the wire drawing process. According to the different textures, the drawing process is also unique. The common ones are straight-grain drawing, chaotic-grain drawing, thread drawing and corrugated drawing.

Ingenuity, unique skills, and meticulous crafting to create high-quality products, this is a criterion and belief in the pursuit of exquisiteness in the manufacturing industry. Zhigao Industry is no exception on the road to the manufacture of automotive power amplifier radiators. fine. Now let's introduce to you a key step in the manufacture of car power amplifier radiators-wire drawing process.

Friends who have been in contact with radiators are no strangers to the term "drawing", but they may not have a thorough understanding of "drawing". In fact, the wire drawing process is a kind of metal processing process. It is a method to improve the surface quality of the work piece by rubbing back and forth on the metal surface by external force to improve the surface finish of the work piece and make the surface texture present a certain regular distribution.

Chicco's car power amplifier radiator can not only improve the appearance of the radiator, but also increase the heat-receiving area and increase the heat-absorbing capacity by means of the wire drawing process. According to the different textures, the drawing process is also unique. The common ones are straight-grain drawing, chaotic-grain drawing, thread drawing and corrugated drawing.

1. Straight wire drawing

Straight-grain wire drawing refers to the processing of straight-line textures on the metal surface by mechanical friction, which can be divided into continuous wire patterns and intermittent wire patterns. The continuous thread pattern can be obtained by using a scouring pad or a stainless steel brush through continuous horizontal straight-line rubbing on the metal surface. At this point, the wire diameter of the stainless steel brush is changed to obtain patterns of different thicknesses. Intermittent silk patterns are generally processed on brushing machines or rubbing machines. Two sets of differential wheels rotating in the same direction are used. The upper group is a fast-rotating grinding roller, and the lower group is a slow-rotating rubber roller. Two sets of rollers pass through, and fine and intermittent straight lines can be brushed.

This is the most commonly used wire drawing process among car power amplifier radiators. The texture direction made according to the requirements should be consistent and run through the entire product, so that the surface of the radiator is evenly distributed and fine texture, making the radiator look more elegant Metal texture, showing silky luster.

2. Random pattern drawing

Random wire drawing. With the help of a high-speed copper wire brush, the aluminum plate is moved back and forth, left and right, and rubbed to obtain an irregular, non-obvious matte silk pattern. This kind of texture requires high processing skills.

3. Thread drawing

Thread drawing is to use a small motor with a round felt on the shaft, fix it on the table, at an angle of about 60 degrees with the edge of the table, and make a carriage with a fixed aluminum plate, and paste it on the carriage. A polyester film with straight edges is used to limit the thread accuracy. Using the rotation of the felt and the linear movement of the carriage, a thread pattern with the same width is rubbed on the surface of the aluminum plate.

4. Corrugated wire drawing

The corrugated wire drawing is generally made on a brushing machine or on a rubbing machine, using the axial movement of the upper group of grinding rollers to rub on the surface of the aluminum panel to obtain a wave pattern.

Zhigao Industry is not only committed to making practical car power amplifier radiators, but also meticulously creating high-end products with exquisite appearance. The drawing process is a particularly critical step on the molding road. Responsible for the product, fulfilling the responsibility for the customer, each step of the pursuit of perfection, thoughtfulness, can create outstanding and valuable products.

Dongguan Zhigao Industrial Co., Ltd. specializes in the production and processing of LED radiators, aluminum electronic radiators, and home audio panels. Welcome to order.