A good heat dissipation system should consist of heat sinks and fans. In fact, the heat sink is the structure inside the heat sink. Generally, the heat sink should be coated with a layer of thermally conductive silicone grease on the contact surface of the electronic component and the heat sink during use, so that the heat emitted by the components can be more effectively transferred to the heat sink, and then radiated to the surrounding air through the heat sink. A heat sink is a device for dissipating heat from electronic components that are easily heated in electrical appliances. They are mostly made of aluminum alloy, brass or bronze in plate shape, sheet shape, multi-sheet shape, etc., such as the CPU central processing unit in the computer. The heat sink, the power tube in the TV, the line tube, and the power amplifier tube in the power amplifier must use the heat sink. Generally, the heat sink should be coated with a layer of thermally conductive silicone grease on the contact surface of the electronic component and the heat sink during use, so that the heat emitted by the components can be more effectively transferred to the heat sink, and then radiated to the surrounding air through the heat sink.

As far as the material of the heat sink is concerned, the thermal conductivity of each material is different. They are arranged from high to low and are silver, copper, aluminum, and steel. However, it would be too expensive to use silver as a heat sink, so the best solution is to use copper. Although aluminum is much cheaper, it is obviously not as good as copper in thermal conductivity (about 50% of copper).

At present, the commonly used heat sink materials are copper and aluminum alloy, both of which have their own advantages and disadvantages. Copper has good thermal conductivity, but it is more expensive, difficult to process, too heavy (many pure copper radiators exceed the weight limit of the CPU), small heat capacity, and easy to oxidize. The pure aluminum is too soft to be used directly. The aluminum alloy used can provide sufficient hardness. The advantages of aluminum alloy are low price and light weight, but the thermal conductivity is much worse than copper. Some radiators take their own strengths and embed a copper plate on the aluminum alloy radiator base.

For ordinary users, the use of aluminum heat sinks is sufficient to meet the heat dissipation requirements.

The radiator for heating in winter in the north is also called a heat sink.

The heat sink occupies an important role in the composition of the radiator. In addition to the active heat dissipation of the fan, evaluating the quality of a radiator largely depends on the heat absorption capacity and heat conduction capacity of the heat sink itself.

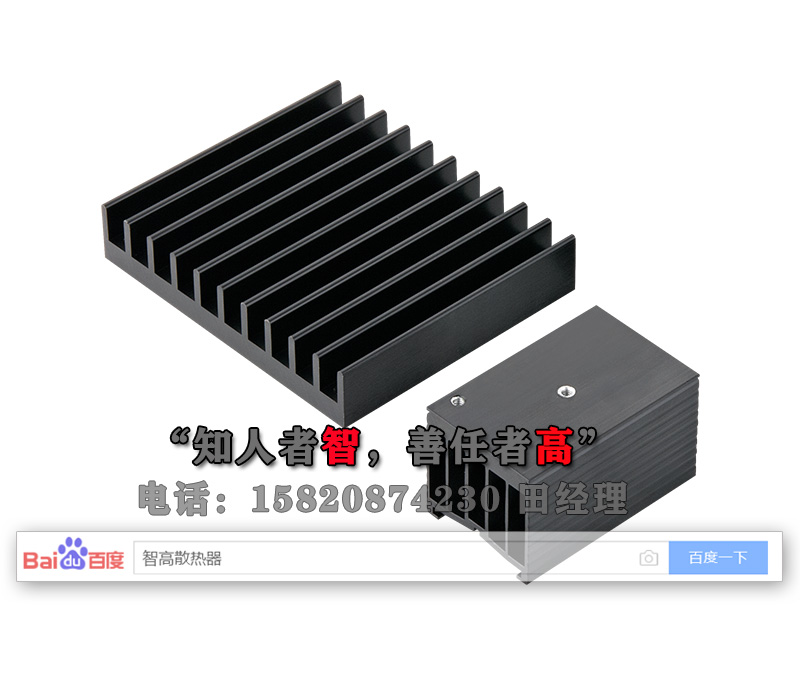

Dongguan Zhigao Industrial Co., Ltd. specializes in the production of customized heat sinks, aluminum automotive power amplifier radiators, aluminum LED radiators, aluminum LED sunflower radiators, aluminum electronic radiators and other products.