The biggest technical problem of LED lighting is heat dissipation. Poor heat dissipation will cause the efficiency of LED lighting to become low and shorten the life of the lamp. Especially in the hot summer weather, the heat dissipation situation of LED lights such as street lights, car lights, display lights and so on under high temperature for a long time is more severe. Before solving the heat dissipation of LED lights, we must first understand the principle of LED lights.

LED lighting is a solid semiconductor device that can convert electrical energy into visible light, that is, light-emitting diodes, which do not have filaments. Therefore, LED lamps do not emit infrared and ultraviolet light sources like traditional light bulbs, and LED light sources do not have radiation heat dissipation functions. . However, the current conversion efficiency of LED lighting is only 20%-30%, which means that about 70% of the electric energy of the LED lamp will be converted into heat when it is working. When the LED lamp generates heat and cannot fully dissipate heat by itself , It is necessary to use a radiator closely connected with the LED lamp bead plate to conduct heat to achieve the purpose of heat dissipation.

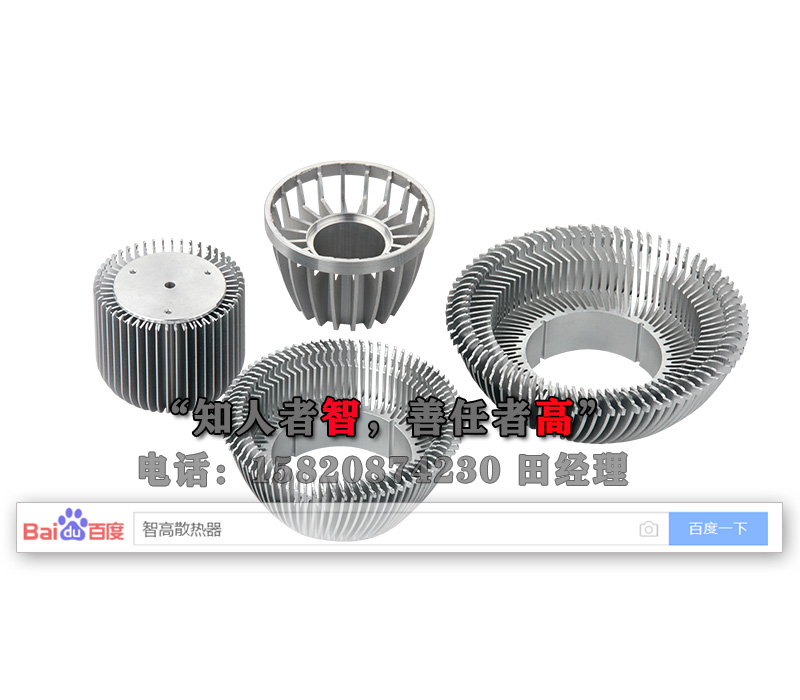

In order to help the LED lights dissipate, in order to help the LED lights to dissipate heat, there are also many types of LED light radiators on the market. Below, Zhigao Industry will introduce several common radiators in the industry to provide solutions to the heat dissipation problems of LED lights.

1. Plastic radiator

The LED light radiator made of plastic has strong plasticity, can be molded into various shapes and applied to products at high temperatures, and has low raw material costs and processing costs, so it can be favored by manufacturers. Ordinary plastics are not strong in heat conduction and heat dissipation. Manufacturers will add metal oxide powder, carbon powder or ceramic powder to the plastic to enhance the heat conduction and heat dissipation capabilities of the LED light radiator. However, plastic radiators also have shortcomings, that is, their thermal conductivity varies greatly and thermal conductivity is not stable. In practical applications, they cannot guarantee a perfect adaptation to the working environment, and plastics are prone to deformation after a long time at high temperatures. Therefore, plastic heat sinks are rarely used in high-power LED lamps, and small LED lamps used for home lighting can meet the requirements.

Two, metal radiator

The LED light radiator made of metal is mainly due to the excellent heat conduction and heat dissipation performance of metal, and copper and aluminum are common. The chemical properties of copper are unstable, and it can be used to make LED light radiators to ensure strong corrosion resistance and longevity, and copper radiators have excellent heat dissipation capabilities, often heat conduction is fast and heat dissipation, but the cost of copper It is often higher because it will not be widely used.

Although aluminum heat sinks are inferior to copper in heat dissipation capacity, the thermal conductivity of pure aluminum is 201W/mK, and aluminum alloys can fully meet the heat dissipation requirements of LED lights. Compared with copper, aluminum is low in density and cost. The LED light radiator produced is not only lighter in weight, but also price can meet user needs. In addition, the plasticity of aluminum is strong, and the LED aluminum radiator can be processed and customized. According to the drawings and samples, the LED light radiator that can match the product is developed. The sun flower radiator and downlight radiator on the market are representative . With the development of technology and the precipitation of experience, manufacturers have mastered the surface treatment processes such as wire drawing, frosting, electroplating, anodizing, etc., making the surface of the cast LED light radiator clean and metallic, high-end unique, and very decorative , Heat dissipation performance and stability have also been improved on the original basis, and Zhi Gao Industrial is one of the manufacturers that can use these processing techniques to provide customers with one-stop service.

Three, graphite radiator

As a new type of heat-conducting and heat-dissipating material, graphite has a thermal conductivity comparable to that of metal, with more stable chemical properties and lighter weight. It has certain advantages when used to make LED light radiators. However, the graphite material itself is expensive, and the later processing costs are even more expensive. Therefore, the use of graphite to make LED lamp heat sinks has yet to be developed in reducing costs.

If LED lighting wants to overcome the heat dissipation problem, it must use a radiator to conduct heat into the air to avoid premature aging of the LED lamp. The choice of which radiator is most suitable must be determined according to the actual application. Only in this way can the advantages of LED light radiators be exploited.

Dongguan Zhigao Industrial Co., Ltd. specializes in producing aluminum automotive power amplifier radiators, aluminum LED radiators, electronic profile radiators, cnc processing and other products.