Let's look at the characteristics of aluminum profiles: aluminum radiators are also called radiator aluminum profiles or sunflower aluminum profiles. Aluminum profile radiators have the characteristics of beautiful appearance, light weight, good heat dissipation performance, and good energy saving effect. In addition, the decorative performance of aluminum profile is very strong: when aluminum is used for decoration or some specific occasions, its surface needs to be processed by anodizing and painting to obtain the corresponding color and surface structure. Aluminum profile has better corrosion resistance. Good, its anodizing performance, surface treatment performance, coating performance are very good.

In my country, aluminum radiators are widely used in industries such as machinery, automobiles, wind power generation, construction machinery, air compressors, railway locomotives, household appliances, etc. due to their superior performance. Without exception, the use of aluminum profiles is becoming more and more popular for radiators, and aluminum extrusion is mainly used. This is because the dimensions of the extrusion forming blanks are good, the production cycle is short and the cost is relatively low.

The heat dissipation performance of aluminum is three times that of steel. The thermal conductivity of aluminum is 167W/m.K, and the thermal conductivity of steel is 50W/m.K. W is heat; M is material thickness; K is temperature. The thermal conductivity coefficient is defined as: per unit length, per K, how many W of energy can be transmitted, the larger the value, the better the thermal conductivity. We can see that the thermal conductivity of aluminum is 3 times that of steel, indicating that the thermal conductivity of aluminum is 3 times that of steel.

Moreover, aluminum radiators not only have good heat dissipation, but also have good thermal conductivity, pressure resistance, and metal thermal strength. The metal thermal strength of aluminum is 2.277W/Kg℃, while 0.4W/Kg℃ of cast iron is 0.76W/Kg℃ of steel, and 1.728W/Kg℃ of copper and aluminum. Aluminum has large heat dissipation capacity, fast heat dissipation, and efficiency. The biggest feature of the aluminum radiator, the appearance is electrostatic sprayed, the design is beautiful, and the decoration is good. The general evaluation is: Comprehensive production does not pollute the environment or water quality. The heat dissipation strength is four times that of cast angle. Lightweight is one-tenth of cast iron. Beautiful and generous, occupying little room space, environmental protection and energy saving. It is in line with the "lightweight, efficient, environmentally friendly, and energy-saving" requirements for the development of radiators in my country.

In terms of making radiators, aluminum alloy is the best choice of materials. Whether it is energy saving, material saving, decoration, price, weight, etc., all have advantages. That is, copper-aluminum, steel-aluminum, stainless steel-aluminum and other composite products with aluminum all contain aluminum. The problem is that it is not as good as steel pipes from the angle of bending, but the heat dissipation of steel pipes is definitely not as good as that of aluminum; from the price point, it is a special point; from the perspective of anti-corrosion, steel is Phosphating first and then anti-corrosion, the process is cumbersome, while aluminum alloy is oxidized or directly anti-corrosive. Therefore, the radiator made of aluminum alloy is superior to the radiator made of other materials in any respect.

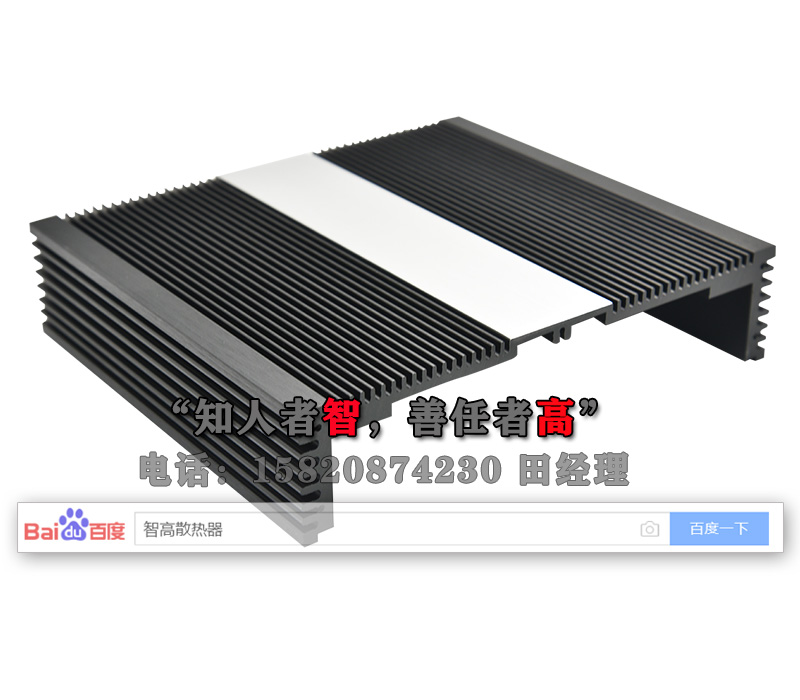

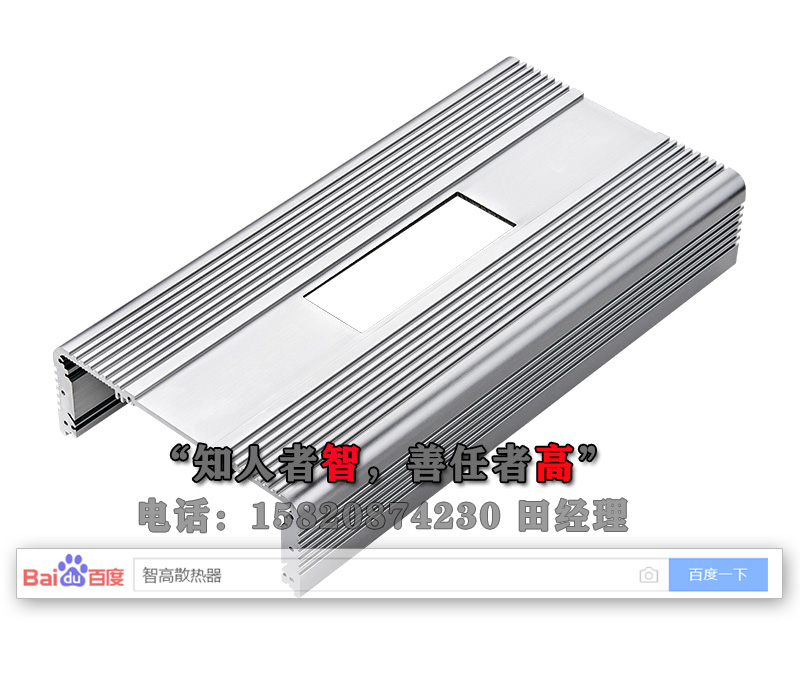

Dongguan Zhigao Industrial Co., Ltd. specializes in producing aluminum automotive power amplifier radiators, aluminum LED radiators, electronic profile radiators, cnc processing and other products.