LED downlights are products developed on the basis of traditional downlights based on the application of LED lighting technology. LED downlights have been widely used in the lighting field because of their high efficiency, energy saving, long life, low price, stable and soft lighting, such as It has applications in housing, shopping malls, hospitals, squares, construction sites, etc.

When producing LED downlights, manufacturers will face a problem, that is, do LED downlights need to dissipate heat? Because in many people’s impressions, LED downlights are highly energy-efficient and have a long lifespan, installing a radiator is tantamount to increasing costs. If the LED downlight itself has superior performance and does not require heat dissipation, installing a radiator will be redundant. In fact, LED downlights used in homes have lower power and generate less heat. However, the accumulated heat will still cause loss of internal parts over time. And those LED downlights with higher power must not be installed with a radiator. Especially in summer, the heat dissipation situation is more severe. For example, the downlights used in squares and shopping malls need to use LED downlight radiators to improve lighting performance and life.

The LED downlight radiator is a part that LED downlight manufacturers have to consider when developing their products. It not only allows the heat to be dissipated in time to ensure the stability of the lighting, but also avoids the loss of high temperature to the downlight. In order to ensure the excellent quality of the LED downlight, the selected LED downlight radiator must also be the upper layer, so which LED downlight radiator should the manufacturer choose? What should be paid attention to when choosing LED downlight radiator?

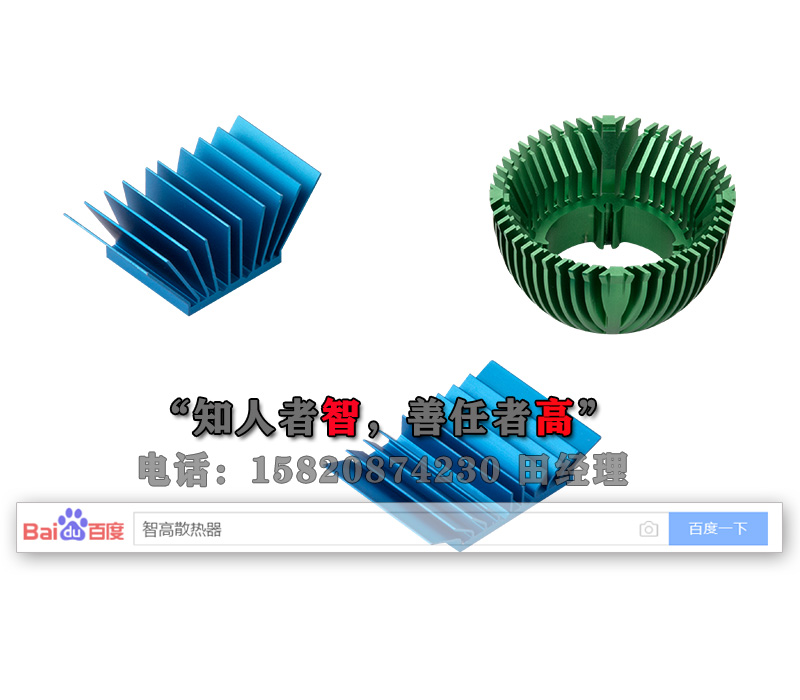

Nowadays, most of the LED downlight radiators with good heat dissipation effect and affordable are made of aluminum profile. This is a physical heat dissipation method optimized on the structure of the downlight. With the excellent heat conduction and heat dissipation ability of the aluminum profile shell, the LED chip can work. The heat generated at the time is transferred to the air. Of course, it is not enough to only use better quality raw materials. LED downlight radiators also need to work hard on the shape design.

Among the LED downlight radiators, the sun fancy radiator has the better heat dissipation effect, which is formed into multiple heat sinks with the help of aluminum extrusion technology, which can increase the contact area between the LED downlight radiator and the downlight and air. Possess higher thermal conductivity and heat dissipation capacity. Many people here think that the more heat sinks and the larger the contact area, the better the heat dissipation effect. In fact, this is a wrong idea. Although more heat sinks can absorb more heat, it also means that the spacing between the heat sinks becomes smaller. At this time, the speed of air flow in each channel becomes smaller, and the deterioration of air convection will make the LED The heat dissipation effect of the downlight radiator deteriorates. Heat conduction is easy but difficult to dissipate. This is the reason why some LED downlights are equipped with a radiator, but the heat cannot be dissipated for a long time and become very hot. Therefore, when designing and producing LED downlight radiators, manufacturers must have a reasonable analysis and planning on the layout of the heat sink to avoid errors that affect the heat dissipation effect.

As an indispensable lighting tool in life, LED downlights are a difficult problem that it has to break through. Installing LED downlight radiators is the most basic and effective method for heat dissipation. When configuring the radiator for the LED downlight, the manufacturer must choose a strong and experienced radiator manufacturer to configure the LED downlight radiator with reasonable materials and structure.

Zhigao Industry is a professional manufacturer of automotive power amplifier radiators, audio radiators, LED radiators and electronic profile radiators. It also engages in the manufacturing and processing of various aluminum and hardware accessories. It has more than ten years of experience in the production of radiators. experience. In the production of LED downlight radiators, a one-stop service from raw material extrusion to surface treatment can be realized. The mold can be customized according to the manufacturer's requirements, and the delivery speed is fast and the price is affordable. The LED downlight radiator produced is made of exquisite aluminum material in raw materials, and is cast into an appearance suitable for installation and use by manufacturers under professional and skilled processing technology. The appearance of the finished product is exquisite and high-end without flaws and scratches, and the quality is strong and durable. In terms of quality and performance, customers can be more assured, so that the manufacturer’s LED downlights have more stable lighting and longer service life with the help of carefully cast radiators.