As a heat dissipation tool with high heat dissipation efficiency, aluminum radiator is widely used in industries such as electronics, electrical appliances, and lighting. However, different aluminum profile radiator manufacturers have different technical processes and refer to different production standards, and the aluminum profile radiators produced will also have good or bad heat dissipation effects. So how can radiator manufacturers produce aluminum radiators with good heat dissipation effects? Next, Dongguan radiator manufacturers will share their experience and tell you how to produce aluminum radiators with good heat dissipation.

1. The bottom thickness design of the radiator

Many people think that the fins are the key to heat dissipation when they come into contact with aluminum heat sinks. In fact, the heat sink at the bottom is also an important part of heat dissipation. The bottom design of the aluminum radiator should adhere to the principle of gradual thinning from the heat source part to both sides. This is to ensure that the heat absorbed by the heat source part can be quickly transferred to the surrounding thinner part to achieve high-efficiency heat dissipation. If the bottom radiator is designed to be flat and the heat in the heat source part is difficult to diffuse, it will affect the radiator to further absorb heat from the heat source.

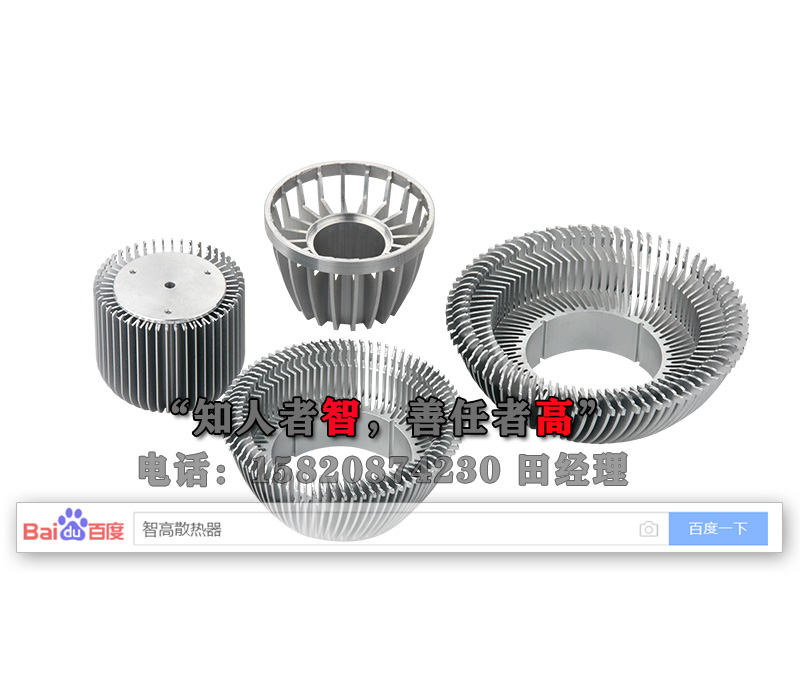

2. Fin design

Designing the radiator into a fin shape not only increases the contact area with the heat source to absorb more heat, but also increases the contact area between the radiator and the air so that the heat can be dissipated into the air faster. Some people here wonder if the more and thicker the fins, the better the heat dissipation effect? In fact, this is not the case. The overall area of the radiator is limited. If there are more fins, there is indeed a larger contact area to absorb more heat, but this also means that the spacing between the fins becomes greater. At this time, the air flow velocity in each channel becomes smaller, and it becomes more difficult for the radiator to dissipate heat into the air. If the fins become thicker, the number of corresponding fins will decrease, and the heat absorption will not necessarily increase. Therefore, when the manufacturer produces aluminum heat sinks, the design of the fins must be reasonably and accurately calculated according to the requirements, and the production must be strictly in accordance with the plan, only in this way can the finished product fully meet the heat dissipation requirements.

3. Aluminum extrusion technology

Through the above introduction, it is not difficult to see that the radiator must have extremely high requirements in shape design and dimensional accuracy, and the radiator must be error-free in the molding process to achieve the expected heat dissipation effect, and here is The help of aluminum extrusion technology is indispensable. Aluminum extrusion molding is a part processing method that exerts strong pressure on the aluminum alloy material placed in the mold cavity to cause the aluminum alloy to produce directional deformation, so as to obtain the required cross-sectional shape, size and certain mechanical properties. The radiator uses aluminum extrusion molding technology to achieve high precision of the finished product, good surface quality, and stable overall structure to ensure the qualified rate of the product. Traditional welding technology cannot achieve such good results. Not only is the accuracy difficult to meet the requirements, but the weld is easily corroded and affects the stability of the overall structure.

4. Anodizing process treatment

The factors that affect the heat dissipation effect of aluminum radiators are not only the area, shape, and convection area of the radiator with air, but also the heat radiation capacity is also a part that cannot be ignored. Radiant heat dissipation is a heat dissipation method in which the surface of the object with higher temperature emits infrared rays and the surface of the object with lower temperature receives heat. The aluminum radiator uses radiant heat to transfer the high heat of the heat source part to the lower temperature part to achieve equilibrium The effect of heat dissipation to improve heat dissipation performance. The ordinary aluminum profile radiator does not have a good radiation heat dissipation effect, and anodization is used to form an oxide film on the surface of the aluminum profile radiator to enhance the heat radiation capacity of the radiator and make the heat dissipation effect of the radiator better. outstanding.

The above is the experience of producing high-quality aluminum radiators shared by Dongguan radiator manufacturer Zhigao Industrial. It is not only to help manufacturers produce aluminum radiators with better heat dissipation effects, but also to help users choose aluminum radiators. A basis for judging good or bad.

Dongguan Zhigao Industrial Co., Ltd. specializes in the production of aluminum profile track light radiators, aluminum profile car power amplifier radiators, aluminum profile LED radiators, electronic profile radiators, CNC processing and other products.