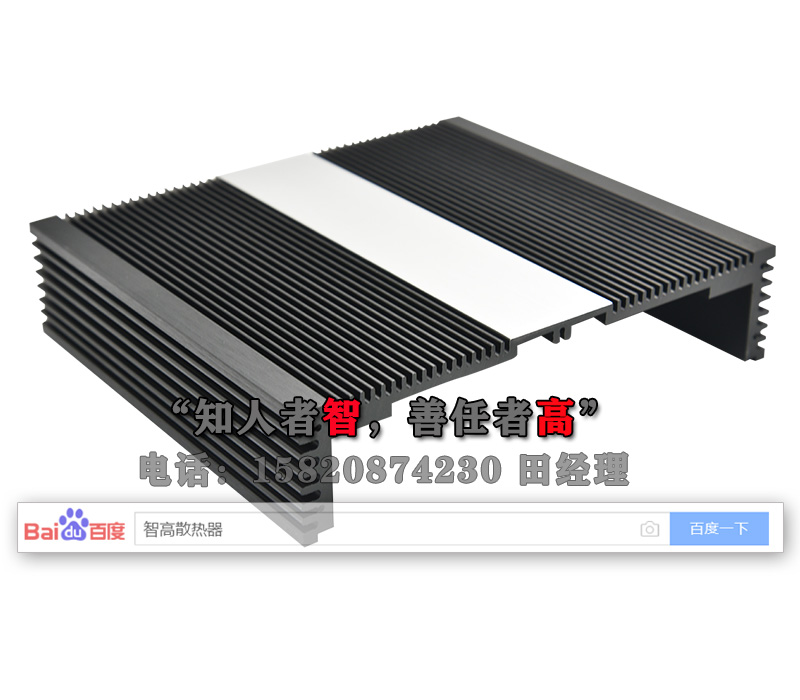

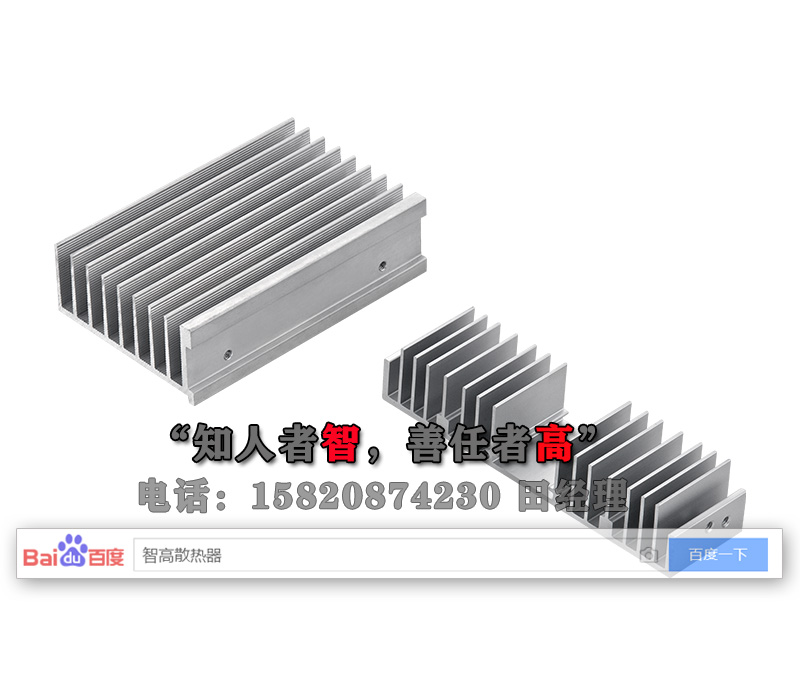

As a material shell widely used in the electronics and electrical industries, aluminum radiators can not only protect the internal power components from bumps, but also help the power components to conduct heat and dissipate heat. Safe and stable operating environment. Of course, to achieve this goal, the premise is that the components and aluminum radiator can be installed well. Next, Dongguan Zhigao Industry will share with you the precautions when installing the aluminum radiator, so that everyone can install the aluminum radiator firmly.

1. Keep a proper distance from the heating components

In order to pursue light weight and small size when producing electronic products and electrical appliances, many manufacturers will minimize the distance between power components and aluminum radiators. In fact, this is wrong. Because the aluminum profile radiator is too close to the internal components, it will not be conducive to the flow of air, so the aluminum profile radiator is inconvenient for heat dissipation, and it will cause loss of heat or heat-resistant components after a long working time. Therefore, when we install the aluminum radiator, we must choose the appropriate spacing, which is neither too wide nor too narrow.

2. Avoid scratches

When installing aluminum radiators, you should try to avoid bumps and scratches, especially the surface coating or oxide layer. Many people think that these coatings are just simple dye layers during installation, and it does not matter as long as there is no scratch on the outside and does not affect the appearance. In fact, the coating has the effects of oxidation resistance and heat radiation ability, which can improve the life and heat dissipation capacity of aluminum radiators.

Three, tightly connected with the component shell

First of all, in order to ensure good contact between the shell of the component and the radiator, the use of insulating pads should be avoided as much as possible, and the contact surface of the component shell and the radiator should be smooth and flat. If insulation is really needed, install the insulating pad The thickness should be between 0.08-0.12mm. Secondly, because the component shell and the radiator are difficult to be closely integrated, there will always be air gaps that are hard to see with the naked eye, so it is generally necessary to apply silicone grease to the connection to ensure that the radiator and the component shell are tightly connected to facilitate heat dissipation. If the aluminum profile radiator is to be fully functional, it must be installed first. If you grasp the matters that must be paid attention to when installing the aluminum profile radiator, you can install it firmly and make the best use of it.