With the rapid economic development and the steady growth of our living standards, almost every household has purchased audio equipment, but many people do not know that the material of the audio panel will directly affect the quality of the audio.

Some people regard audio as a musical instrument, which is a very big misunderstanding. The speakers of musical instruments need to be thin in order to vibrate the sound of the strings. The sound is on the contrary, there is no need for speaker vibration at all. The sound of the sound is produced by the speaker and introduced by the amplifier. It only needs the sound to resonate in the speaker and emit super bass, without the need for speaker panel vibration.

The quality of the sound panel greatly affects the heat dissipation capacity of the sound. The outer surface of the sound without sufficient heat dissipation capacity will be severely hot. The louder the sound, the hotter it will be. Severe heat will also affect the normal use of the speakers, and even some speakers will be damaged due to the inability to dissipate the heat.

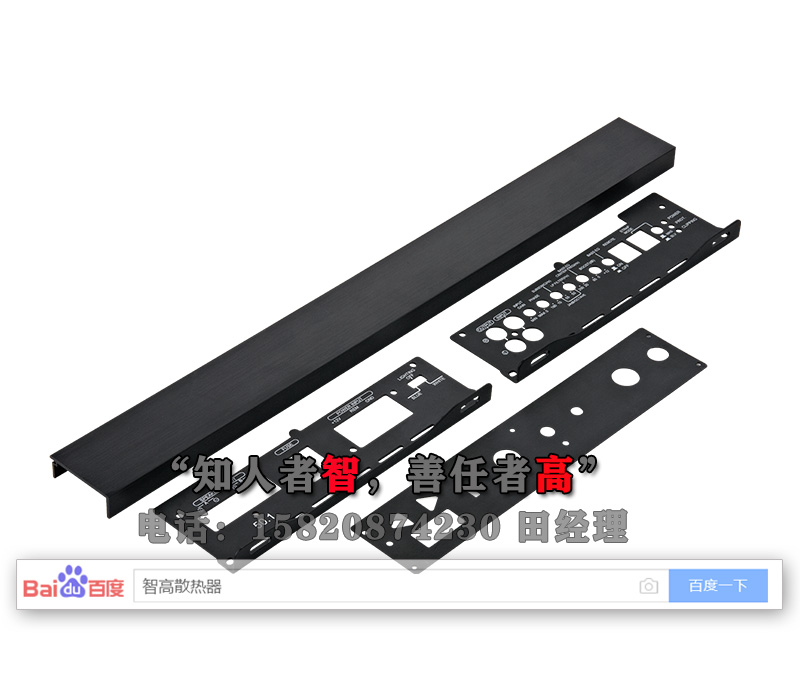

If you want the audio to be used for a long time without getting hot, it is very important to choose a high-quality audio panel. Generally speaking, the quality of the audio panel is directly reflected in the material used for the audio panel. In fact, it is true. The requirements for high-quality audio panels are higher. Next, Chicco will take you to understand the requirements of high-quality audio panels:

1. Material requirements: Choose materials with good thermal conductivity, which play a decisive role in the heat dissipation performance and energy saving effect of the heat sink. The order of thermal conductivity of commonly used heat sink materials for heat sinks is: copper (401W/mK), aluminum alloy (237W/mK), steel (80W/mK), stainless steel (50W/mK). The thermal conductivity of copper-aluminum composite heat sink can only be calculated based on aluminum alloy, and the thermal conductivity of steel-aluminum composite heat sink can only be calculated based on steel.

2. Non-contact thermal resistance: For heat sinks made of two materials (copper-aluminum, steel-aluminum, fin-wound tubes, etc.), due to the manufacturing process, there is a gap in the contact surface, so there is a "contact thermal resistance". The existence of contact thermal resistance will affect the thermal conductivity and heat dissipation efficiency. And because the expansion coefficients of the two materials are different, as time goes by, the contact gap will become larger and larger, and the contact thermal resistance will also become larger. Therefore, high-quality heat sinks require no contact thermal resistance.

3. Strong compressive strength: high strength requires higher compressive strength (≥1.0Mpa).

4. Strong corrosion resistance: long life and good corrosion resistance can make the heat sink have a long service life, and the lighting technology accessories ensure the long service life of the product.

5. Ensure safety: no scalding of other components. High-quality radiators require good heat dissipation performance, low surface temperature, and no scalding of other components.

6. Smooth appearance: beautiful and generous high-quality heat sinks require flat welds, beautiful appearance and decorative.

7. To comply with the relevant national standards, the audio panels produced by Dongguan Zhigao Industrial Co., Ltd. are produced in strict accordance with the national standards.