Anyone who is engaged in the electronic product industry or has a deep understanding of electronic products will know that most of the electronic products we use are equipped with an aluminum alloy heat sink or aluminum alloy heat dissipation shell. The role of this aluminum alloy heat sink is not only to build electronic products Complete and sturdy frame, and to help the internal CPU to dissipate heat, to ensure a safe and secure working environment when electronic products are in operation.

This traditional heat dissipation method uses aluminum alloy to transfer internal heat to the air for heat dissipation. It has always had a good effect, but with the development of technology, new types of radiators have appeared in our field of vision one after another, such as wind Cold radiators and water-cooled radiators. These active radiators have more obvious heat dissipation effects and are gradually being favored by many people.

In this case, recalling the traditional aluminum alloy heat sink, many people feel that the advantage is not obvious and there is no need to use it. But is this really the case? Can traditional aluminum alloy heat sinks really only be eliminated in the face of new radiators? Next, Chicco Industry will take you in-depth analysis.

The operation of air-cooled radiators and water-cooled radiators relies on the drive of electric energy. The heat dissipation effect is indeed a little known, but their installation also depends on the reasonable application of the electronic product space. Today’s electronic products are pursuing thin and light, and if you want to install air-cooled or water-cooled inside, not only the installation technology is very demanding, but it is not easy to pursue the light and thin volume, so the price is often Relatively high. Another more affordable and effective method is external air cooling, but in this case, the effect of aluminum alloy heat sink is indispensable, because air-cooled heat dissipation is to dissipate the heat from the electronic surface into the air faster, if there is no aluminum alloy With the existence of the heat sink, the internal heat cannot be dissipated, and the air-cooled radiator has no practical value.

From the above, it is not difficult to find that although the new type of radiator has advantages in terms of heat dissipation, it still has shortcomings in convenience, and the aluminum alloy heat sink can achieve better results. Of course, in the face of the competition brought by new radiators, aluminum alloy heat sink manufacturers are also constantly improving to improve the heat dissipation effect, the most obvious of which is the structural transformation.

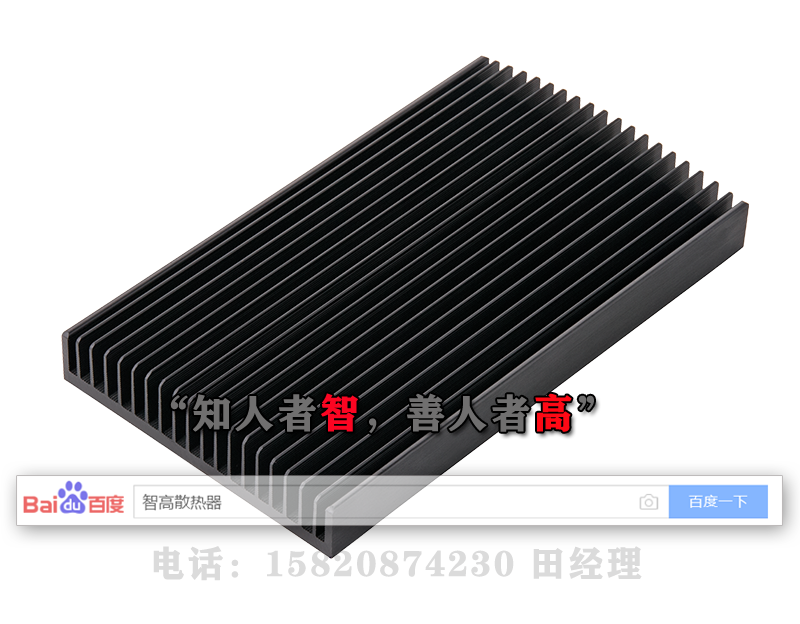

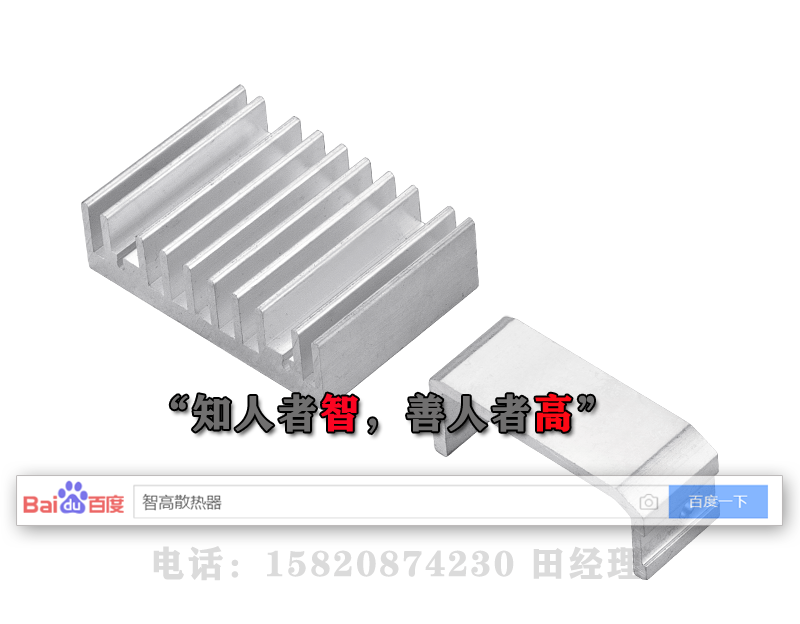

This structural transformation is to design the aluminum alloy heat sink into a fin type instead of a simple metal plate. In this case, the heat dissipation area of the aluminum alloy heat sink is increased, which can not only absorb more Heat, but also can improve the heat dissipation efficiency by increasing the convection area with the air. However, this is also a test of the strength of aluminum alloy heat sink manufacturers, because it is not an easy task to produce a sturdy and well-sized heat sink.

Traditional aluminum alloy heat sinks are not without advantages in front of many new radiators. They still have their own place and unique role in the field of heat dissipation, and the enterprising spirit of manufacturers is indispensable here. Zhigao Industry has been on the road of forge ahead, professionally processing customized aluminum alloy heat sinks, learning from each other's strengths and making up for their weaknesses, in order to achieve more perfect heat dissipation.