The speed of upgrading electronic products is getting faster and faster, and the competition among major manufacturers is also intensifying, and they are constantly innovating and optimizing the appearance, features, and performance of their products to prevent being left behind in the market. The types and functions of electronic products are different, but one thing is in common, that is, the need to install electronic heat dissipation shells. The shell is not only an important part of beautifying the appearance of electronic products, but also the key to improving the heat dissipation performance of electronic products.

Installing a suitable electronic radiator shell for electronic products is an indispensable part of casting electronic products, and the appearance size, shape details and heat dissipation requirements of the electronic radiator shells applied to it are different. Achieving excellence in appearance and performance is not an easy task. Next, Chicco Industry will introduce to you how the electronic radiator housing takes into account the appearance and heat dissipation performance.

1. In appearance

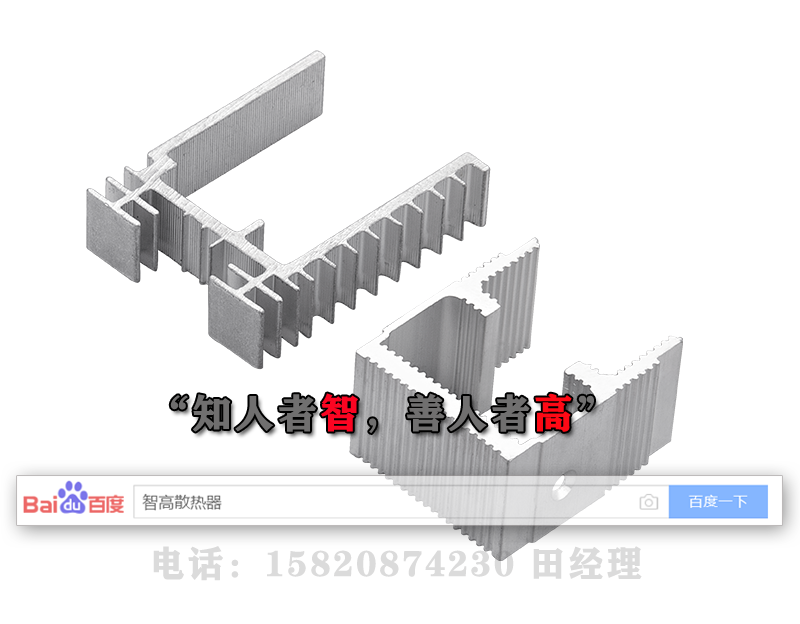

Electronic products are not completely sealed by the shell. Electronic products have buttons or sockets. This requires holes in the shell of the electronic radiator. Different electronic products have different requirements for the location and size of the holes, which requires finding electronic heat dissipation. The manufacturer of the housing of the device carries out the mold opening customization. The common processing methods of punching are stamping and CNC processing. The former can perform rapid surface processing under the premise of saving costs, and the latter can perform various complex surface treatments to meet various complex needs, resulting in general stamping difficulties. Complex holes, pattern shapes and textures formed.

Many electronic products pursue uniqueness and diversity in appearance, which requires other processing. The common ones are oxidation, wire drawing, paint baking, sandblasting, laser carving, etc. The effects formed by different surface processing methods are also different, and they are often combined and used in a variety of processes during production and processing. The electronic radiator shell can be exquisite and beautiful in appearance, high-end and dazzling.

2. Heat dissipation performance

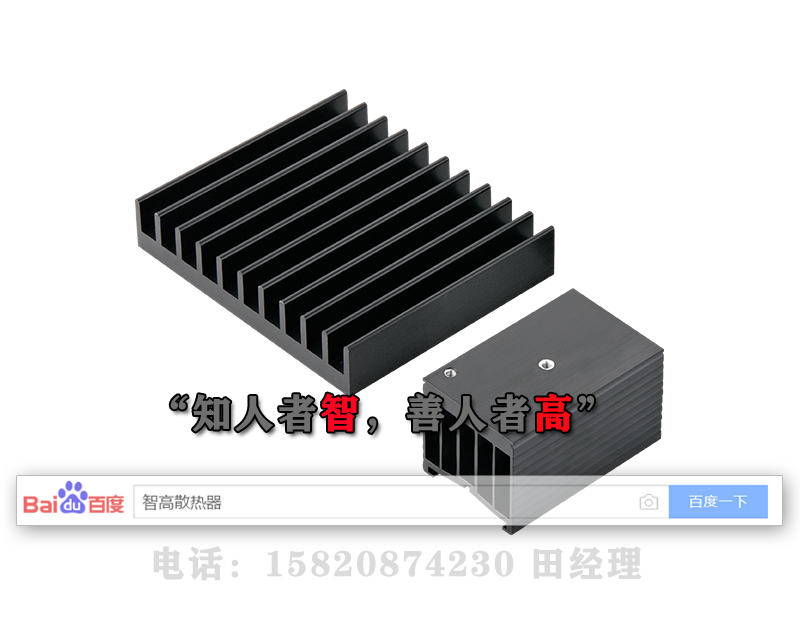

Heat dissipation has always been a problem that electronic products have to face and deal with during the production of electronic products, and the installation of electronic radiator shells is still an indispensable way for electronic products to conduct natural heat dissipation. With the help of the electronic radiator shell, the high heat generated inside is quickly dissipated to the outside air to protect the safety of electronic products. Of course, different electronic products have different requirements for heat dissipation performance, which requires manufacturers to optimize the structure.

The so-called structural optimization actually depends on the processing technology introduced above, such as processing inside the electronic radiator shell to form textures, patterns or extruding fins. This is not for the pursuit of aesthetics, but also to increase the shell and heat source. The contact area of the electronic heat sink can absorb more heat and dissipate the heat more efficiently.

In order to balance the appearance and heat dissipation performance of the electronic radiator shell, and achieve excellent results, it actually requires the manufacturer to carefully consider it in the early stage. Dongguan Zhigao Industry adheres to a professional and responsible attitude, pursues cost savings for customers, can formulate reasonable production and processing plans, and produces radiator shells that can withstand the test in quality and details.