Nowadays, the frequency of electronic products replacement is getting faster and faster. Manufacturers have been struggling to improve the performance of electronic products. However, no matter how the times change, and no matter how the performance of electronic products changes, electronic products are inevitable. Faced with the problem of heat dissipation, especially now that the performance of electronic products continues to rise, energy consumption is increasing, but the space is constantly shrinking. Therefore, the heat dissipation situation of electronic products has become more severe, and a radiator with high quality and excellent performance is needed to efficiently dissipate heat.

When manufacturers add radiators to electronic products, they will look for professional radiator manufacturers for processing and customization, so that the manufactured radiators can perfectly fit the product. For manufacturers, the most concerned about radiator processing customization is nothing more than the strength and production cost of the processing plant. The former can be known through actual investigations. If the latter is not clear to many manufacturers, then decide the radiator What are the factors of processing custom prices? How can the production cost be reduced? Let’s take a look at Chicco Industries.

1. Material

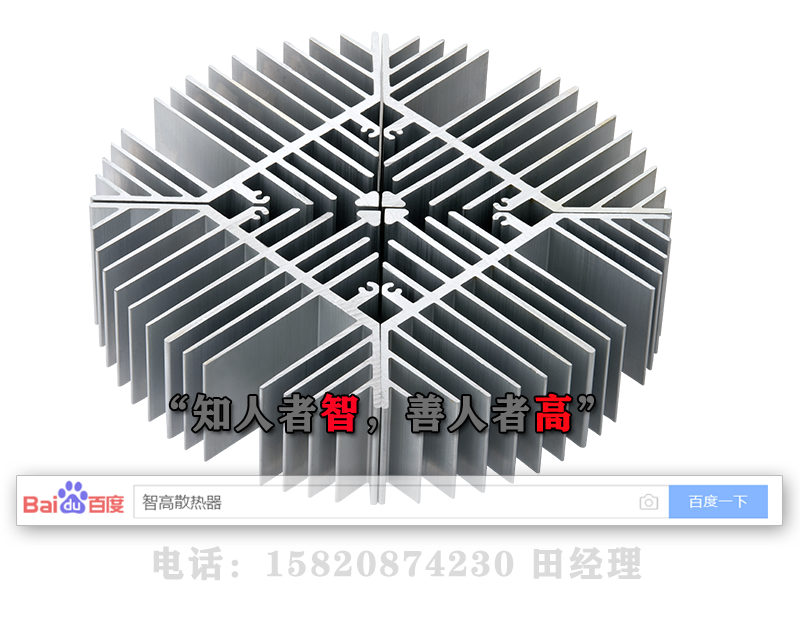

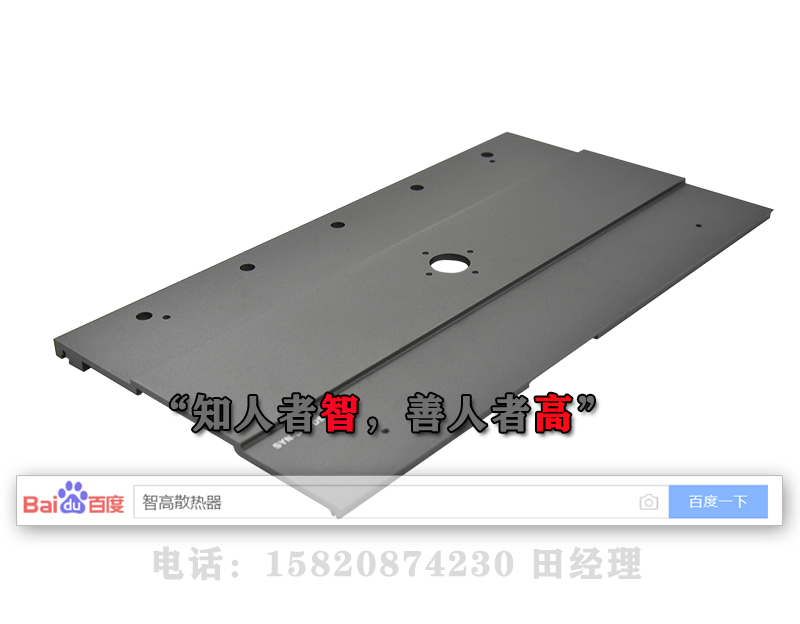

The material selected for the radiator is not only the key to determining the performance of the radiator, but also the basis for determining its price. Different raw materials have different prices, and the difficulty of processing is also very different, so the final product prices are also very different. For example, we have seen many electronic products using plastic radiator shells. This is indeed very cheap in price and very simple in shaping, but the heat dissipation performance is difficult to meet the standard, so it is difficult to satisfy the public The heat dissipation requirements of similar electronic products. The aluminum radiator is one of the most popular types on the market today. It is relatively affordable in price, durable, and excellent in heat dissipation. Of course, many new radiator materials have gradually appeared in recent years, with unique advantages in performance, but it is difficult to gain popularity because of the high cost.

Two, mold opening

Mold opening is an indispensable step for radiator processing and customization, because only with the help of molds can large-scale, fast, and accurate processing and production be realized to ensure the accuracy of each radiator without errors. However, the cost of mold opening is often very high. For some manufacturers who only produce small batches, sometimes the price of mold opening is even higher than the price of the product itself; and for those long-term cooperation, large quantities are required For manufacturers, the price of mold opening is not so obvious. After all, there is nothing more important than quick supply of products and qualified quality.

Three, processing technology

Different electronic products have different requirements for the size and appearance of the radiator, which requires the radiator processing plant to process the surface of the radiator later to form different effects. And the price formed by different processing technology is also different, the words here still have to be based on the specific needs of the manufacturer.

Factors affecting the price required for radiator processing and customization exist in all aspects. If you want to truly save processing costs, you must find a strong and reliable production and processing plant. The two parties can only work in this area after detailed communication. Zhi Gao Industrial focuses on the processing and customization of various aluminum profile radiators, and can formulate detailed and economical processing plans according to the needs of businesses, so that the processed finished products can not only meet customer needs, but also help customers save costs to the greatest extent.