A flashlight is a life tool that we often use when we are young. In that era when the lighting conditions were not particularly good, it would be very convenient to have a flashlight by our side when we go out at night. And now that the mobile phones we use all have the function of a flashlight, the flashlight has slowly disappeared from our field of vision, but this does not mean that the flashlight has been eliminated. In our field camping, medical lighting, article appreciation, etc. Also need to use it.

Although flashlights are not as common as before, as our quality of life requirements increase, the quality requirements for flashlights are getting higher and higher. Previous flashlights were mostly made of plastic, which was not only fragile and not resistant to falling, but also not easy to dissipate heat and could easily cause the internal flashlight to burn out. Therefore, we always face the situation of replacing a new flashlight.

This kind of flashlight is obviously not suitable for survival in today's market, even if the price is cheap, it will not have an advantage. So what is the flashlight that can cater to the market demand today? In what ways has the flashlight been improved? Let's take a look at Chicco Industrial.

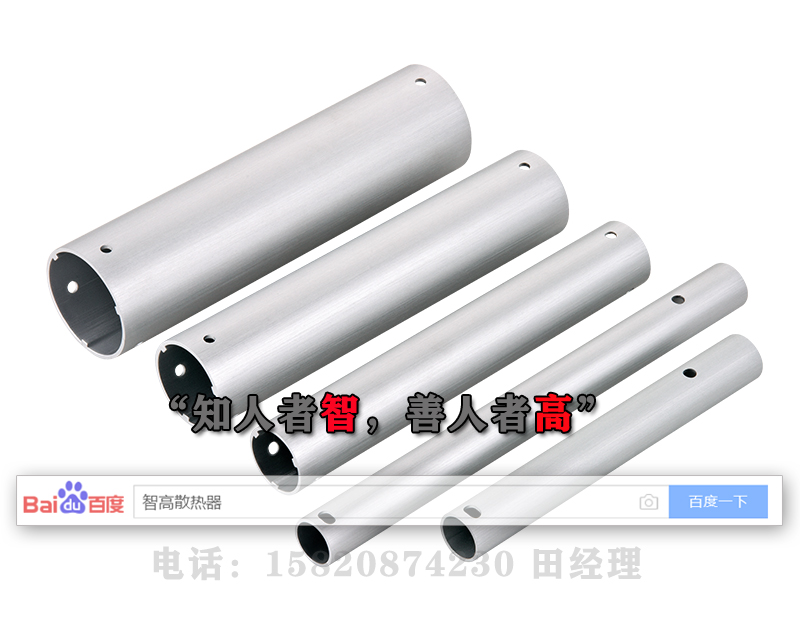

Today's flashlights use LED lights with stronger lighting performance in the light source, which have the characteristics of high brightness, long life and long range, but it also needs to be supported by a good flashlight shell. Plastic shells like the previous ones used in pursuit of low cost will definitely be eliminated. Nowadays, most of the materials used in the shell molding are aluminum alloy. Although this material is higher in price than plastic, it is still considered. In the economical range. Aluminum alloy has high plasticity. It can be processed and customized into various shapes under the actual operation of professional processing plants. The key products are strong and light. It is easy to carry and convenient for daily lighting in short-term or out-of-home lighting.

In addition, although the flashlight uses LED lights, the heat generation is not as exaggerated as in the past, but heat dissipation is still an inevitable problem in practical applications, because if the internal heat is not dissipated for a long time, it will affect the internal parts. Cause loss and affect the normal service life of the flashlight. The aluminum alloy has good heat conduction and heat dissipation capabilities, which can efficiently and quickly dissipate heat, providing protection for the safety of the flashlight.

Which material is the best choice for flashlight shell processing? Generally speaking, aluminum alloy material has certain advantages and has been well applied. Zhigao Industry specializes in the production and processing of all kinds of aluminum alloy shells, and its business involves flashlight shells, audio shells, LED lamp shells, electronic product shells and other fields. It uses excellent aluminum profiles to make solid shells, and uses superb processing technology to cast excellent appearance effects. , Let what you see is what you need.