In 2015, the external market environment was relatively difficult, but under the leadership of President Li, all cadres and employees focused on the goals set at the beginning of the year, with one heart and one mind, pioneering and enterprising, quality first, and dedicated service, which have been highly recognized by customers! With the joint efforts of everyone, we have achieved satisfactory results and completed the business goals set at the beginning of the year, laying a solid foundation for the company to respond to the market crisis and continue to develop in the coming year. The specific results achieved are as follows:

1. Achieve a 22% increase in turnover;

2. Introduce ERP system and machine automation project;

3. The whole company has no appropriation return, no batch error quality accidents throughout the year;

4. No safety accidents and work-related accidents occurred throughout the year;

5. Based on the continuation of the previous salary and benefits, the salary of all employees has been increased by 10%;

6. Hire an external consulting company to train employees on lean production knowledge;

7. Assist customers and participate in the development of a variety of new products.

In 2016, we will work harder and adhere to the tenet of product quality first and customer service, and all employees will work together for the development of the company!

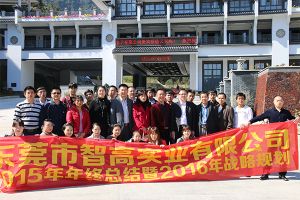

On January 17-18, 2016, an annual meeting was held at Xinfeng Yuntianhai Hot Spring Hotel and surrounding attractions in Shaoguan City, to summarize the company’s work in 2015 and formulate a 2016 business plan, and to thank all employees for their hard work in the past year. And pay silently. All the backbones and elites of Dongguan Zhigao Industrial Co., Ltd. participated in this event!

Dongguan Zhigao Industrial Co., Ltd. specializes in processing aluminum automotive power amplifier radiators, aluminum home audio radiators and aluminum LED radiators. It has a CNC machining center and manufactures various aluminum and hardware accessories. The company has hundreds of aluminum extrusion machines, sawing machines, punching machines, drilling machines, tapping machines and other equipment. It has an independent oxidation plant and provides one-stop services for raw material extrusion, mold design and manufacturing, mechanical deep processing and various surface treatments.