In this case, the heat dissipation coefficient is an important parameter to evaluate the heat dissipation performance of the radiator. There are many influencing factors, among which the thermal conductivity of the radiator material and the welding quality have a great influence on it. Increasing the heat dissipation coefficient can improve the heat dissipation efficiency, so that the heat sink can achieve the best heat dissipation effect with a smaller size and quality. Therefore, thermal conductivity is very important to the heat sink material.

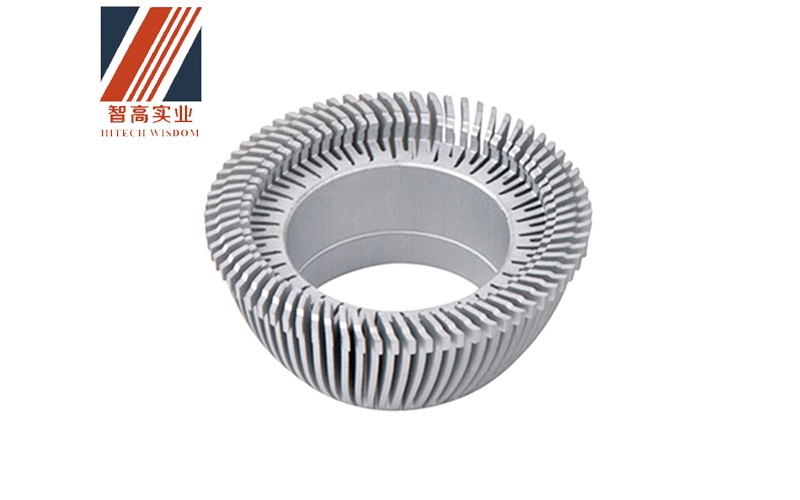

The working conditions of the radiator are bad, and some radiators have long-term flow of coolant, which may be mixed with corrosive and harmful components, which have rust and corrosion effects on the radiator. Therefore, in order to ensure the reliable heat dissipation of the radiator, the material performance of the radiator has the following requirements:

① has good thermal conductivity

② has a certain strength and strong corrosion resistance

③ Good processing performance and brazing performance.

④ Good economy.

Aluminum is the material of choice for radiators: the biggest advantage of aluminum is its light weight, with a specific gravity of only one-third of that of copper. With the same volume, the quality can be greatly reduced; aluminum resources are much richer and the cost is much lower than copper; The thermal conductivity of aluminum is lower than that of copper, only 60% of copper. However, due to the tin protection layer with lower thermal conductivity of copper radiators, the thermal efficiency of aluminum radiators is higher than that of copper radiators. In addition, aluminum is also It has good special processing performance: although aluminum radiator has the advantages of light weight, low raw material cost, and good heat dissipation performance.

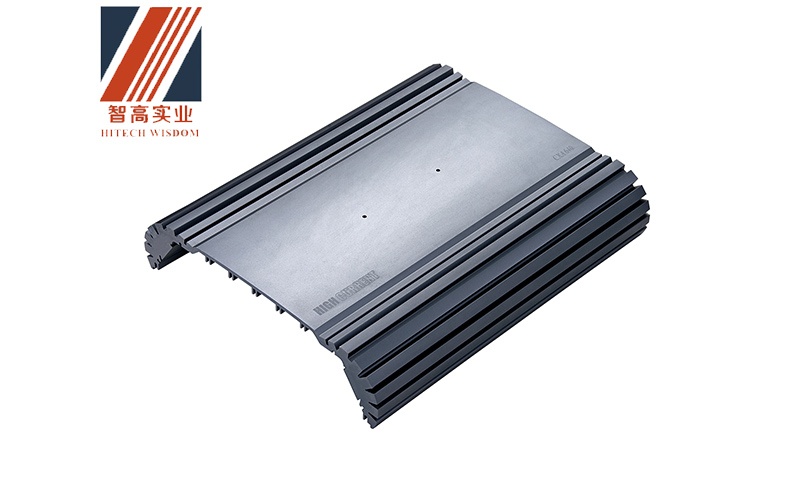

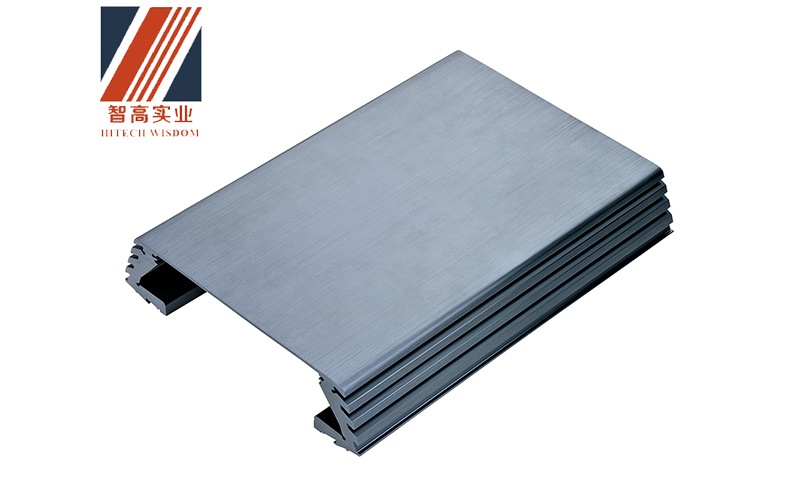

Dongguan Zhigao Industrial Co., Ltd. specializes in processing aluminum automotive power amplifier radiators, aluminum home audio radiators and aluminum LED radiators.